Introduction to Hot Rolled Steel Coil: Benefits, Features, and Applications

What is Hot Rolled Steel Coil?

Hot rolled steel coil is a versatile and widely used material that undergoes a manufacturing process in which the steel is heated above its recrystallization temperature and then rolled into thin sheets or coils. This process not only shapes the steel but also increases its ductility, making it easier to form into various shapes and sizes. Hot rolled steel coil is typically used for structural applications and is found in industries ranging from construction to automotive manufacturing. The material is known for its strength, durability, and cost-effectiveness.

Benefits of Hot Rolled Steel Coil

- Cost-Effective Manufacturing Process

Hot rolling is a relatively simple and cost-effective process, which makes hot rolled steel coils less expensive compared to cold rolled steel. This makes it an ideal choice for large-scale manufacturing and industries where cost efficiency is a priority. - Excellent Workability

Hot rolled steel is easier to work with than cold rolled steel, as it is more ductile and can be shaped into large plates or coils. This makes it well-suited for applications that require extensive shaping, bending, or welding. - Strength and Durability

The high temperature at which hot rolled steel is processed gives it increased strength and toughness. This makes it suitable for heavy-duty applications, including structural components, beams, and frames that need to withstand high stresses and forces. - Large Size and Thickness

Hot rolled steel coils can be produced in large sizes and thicker gauges, which is advantageous for applications requiring steel sheets or plates of varying thickness, such as construction beams and industrial machinery parts. - Reduced Residual Stress

The hot rolling process helps to relieve internal stresses within the steel, which can improve its performance in later manufacturing processes such as welding and machining. - Variety of Finishes and Surface Qualities

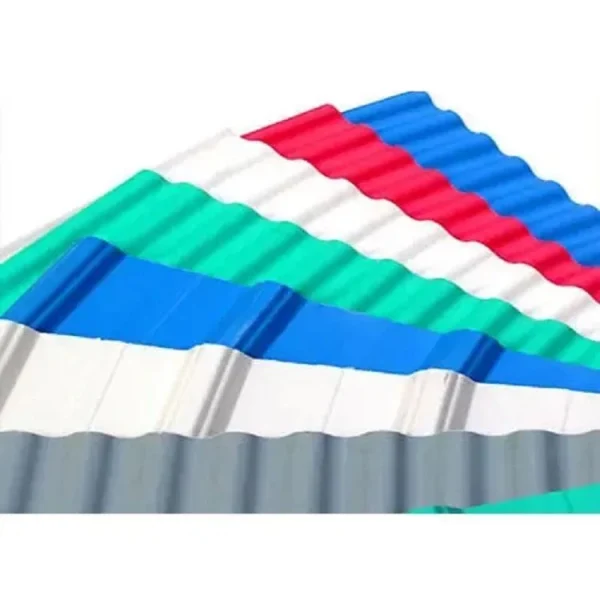

While hot rolled steel coils typically have a rough, mill scale finish, they can also be produced with a variety of coatings or further treatments to improve surface quality, corrosion resistance, and overall aesthetic appeal.

Applications of Hot Rolled Steel Coil

- Construction and Structural Steel

Hot rolled steel coils are widely used in the construction industry for structural elements such as beams, columns, and frames. Their high strength and ability to withstand heavy loads make them ideal for large buildings, bridges, and infrastructure projects. - Automotive Manufacturing

Hot rolled steel coils are used in the production of automotive components such as chassis, body panels, and structural parts. The material’s strength and cost-effectiveness make it a popular choice for car manufacturers. - Heavy Machinery and Equipment

Hot rolled steel is used to manufacture large components for heavy machinery, including plates, structural frames, and equipment housings. Its durability and toughness are crucial for industries such as mining, construction, and manufacturing. - Pipelines and Oil & Gas Infrastructure

Hot rolled steel coils are commonly used in the oil and gas industry for the production of pipelines, tanks, and storage vessels. The material’s strength and resistance to environmental factors make it ideal for use in harsh conditions. - Metal Fabrication

Due to its workability and versatility, hot rolled steel is used in various metal fabrication processes, such as cutting, bending, and welding, to create products like machinery parts, storage tanks, and structural supports. - Agricultural Equipment

Hot rolled steel coils are used to produce agricultural machinery and equipment, including plows, trailers, and storage containers. Its strength and ability to withstand heavy use make it perfect for rugged agricultural environments. - Shipbuilding and Marine Industry

In the shipbuilding industry, hot rolled steel coils are used to manufacture ship hulls, decks, and structural components. Their resistance to impact and high durability ensure that the materials can withstand the tough conditions of the marine environment.

Comparison with Other Types of Steel Coils

Hot rolled steel coils are often compared to cold rolled steel coils, and each has its advantages depending on the application. While cold rolled steel has a smoother surface finish and higher precision, hot rolled steel is preferred for applications where strength and large size are the primary requirements. Hot rolled steel is typically more cost-effective and is better suited for projects that do not require tight tolerances or a polished surface finish. In contrast, cold rolled steel is ideal for applications that demand a more refined surface and higher mechanical properties.