Introduction to Galvanized Steel Coil: Benefits, Features, and Applications

What is Galvanized Steel Coil?

Galvanized steel coil is a type of steel that has been coated with a layer of zinc to prevent corrosion and enhance its durability. The galvanizing process involves immersing the steel in a molten zinc bath, creating a protective barrier that increases the material’s resistance to rust, weathering, and environmental factors. Galvanized steel coils are widely used in various industries, such as construction, automotive, and manufacturing, due to their strength, longevity, and resistance to corrosion.

Benefits of Galvanized Steel Coil

- Corrosion Resistance

The primary advantage of galvanized steel coils is their superior resistance to corrosion. The zinc coating protects the steel from rust and environmental factors such as moisture, salt, and chemicals, making it ideal for use in outdoor and marine environments. - Durability and Longevity

Galvanized steel coils offer an extended lifespan compared to untreated steel. The zinc coating acts as a sacrificial layer, ensuring that the steel remains protected from corrosion for years, even in harsh conditions, thus reducing maintenance and replacement costs. - Cost-Effective

While galvanized steel coils may have a higher initial cost than non-coated steel, their enhanced corrosion resistance and durability make them a more cost-effective option in the long run, especially for outdoor and high-exposure applications. - Improved Aesthetic Appeal

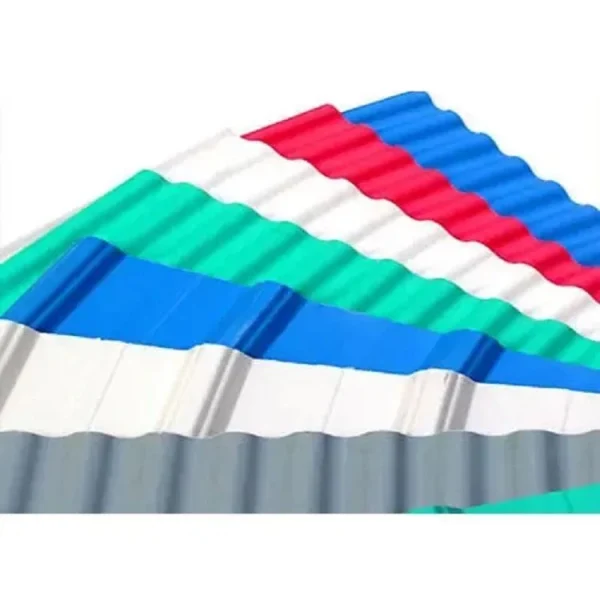

Galvanized steel coils have a clean, shiny finish that is both functional and visually appealing. This makes them suitable for applications where both performance and aesthetics are important, such as architectural projects or consumer goods. - Environmental Sustainability

Zinc is a naturally abundant and environmentally friendly material, and galvanized steel is fully recyclable. The galvanizing process itself produces minimal waste, making galvanized steel a sustainable and eco-conscious choice for construction and manufacturing. - Enhanced Strength and Toughness

Galvanized steel retains the strength and toughness of the base steel, while the added zinc coating enhances its resilience to impact, wear, and environmental stresses. This makes it a versatile material for both structural and decorative applications.

Applications of Galvanized Steel Coil

- Construction and Building Materials

Galvanized steel coils are widely used in the construction industry for roofing, siding, gutters, and structural components. Their corrosion resistance makes them ideal for both residential and commercial buildings, particularly in harsh climates or coastal regions. - Automotive Industry

The automotive industry utilizes galvanized steel for manufacturing parts such as body panels, undercarriages, and chassis components. The material’s corrosion resistance helps extend the lifespan of vehicles, reducing the need for frequent repairs and replacements. - Agricultural Equipment

Galvanized steel is used in the production of agricultural machinery and equipment, such as silos, barns, and storage containers. The material’s resistance to corrosion ensures that it performs well in agricultural environments, where exposure to moisture and chemicals is common. - Home Appliances

Galvanized steel coils are used in the manufacture of household appliances like refrigerators, washing machines, and ovens, providing durability and protection against corrosion in humid and high-use environments. - Outdoor and Industrial Furniture

Galvanized steel is commonly used for outdoor furniture, fences, and storage solutions, offering both strength and protection against the elements. Its ability to withstand rain, sun, and temperature fluctuations makes it a durable choice for long-lasting outdoor products. - Electrical and Power Infrastructure

In the electrical and power sectors, galvanized steel coils are used for manufacturing power transmission components, poles, and equipment enclosures. Their corrosion resistance is crucial for maintaining the integrity of electrical infrastructure exposed to weather and environmental wear. - Signage and Advertising

Galvanized steel is often used for outdoor signage and advertising materials due to its resistance to weathering. The material’s durability and aesthetic appeal ensure that signs maintain their structural integrity and visual appearance for extended periods.

Comparison with Other Steel Coatings

Galvanized steel coils are often compared to other coated steels, such as Galvalume or prepainted steel. While Galvalume offers superior heat reflectivity and corrosion resistance in certain environments, galvanized steel is preferred for its long-term protection against moisture and rust. Galvalume’s aluminum-zinc coating is ideal for applications that require high durability in extreme climates, whereas galvanized steel remains the go-to option for general-purpose corrosion resistance and lower cost.