Well, now, let me tell y’all about this thing called GI sheet. I reckon most folks around here ain’t heard of it, but I’ve got a bit of a story to share. You see, GI stands for Galvanized Iron, and it’s not just any old iron sheet, no ma’am. It’s a special kind of steel sheet, the kind they coat with zinc to make sure it don’t rust or fall apart too quick. I reckon that’s real handy, especially if you need something to last long and hold up in all kinds of weather. So let’s sit down and take a little closer look at what this GI sheet is all about.

Now, y’all might be wonderin’, why do they go and coat a regular steel sheet with zinc in the first place? Well, I’ll tell ya, it’s all about protection. Zinc keeps the steel from rustin’ and corrodin’ when it gets wet or exposed to the elements. And trust me, that’s important if you’re buildin’ stuff that needs to stand the test of time. Whether it’s the roof over your head or some fancy metal for a fence, GI sheet will make sure it don’t give up too soon. A little bit of zinc goes a long way, I tell ya.

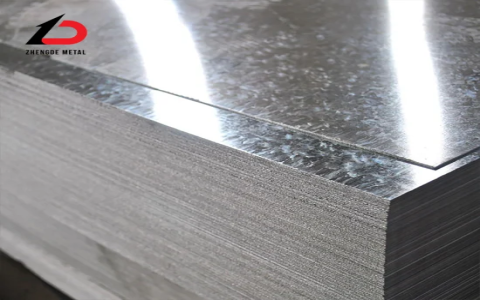

What’s it made of? Well, GI sheet starts with a base of steel, which is then dipped in a hot bath of zinc. This hot-dip process coats the steel all over, so the zinc’s stickin’ real good and tight. After that, it gets dried and cut into sheets, ready to be used for all kinds of things. And depending on how thick you want the coating, you can get different kinds of GI sheets. Some are thicker, others thinner, but they all serve the same purpose—keep that steel from rustin’ away.

How thick is this stuff, you ask? Well, it depends on what you need it for. You might see these sheets listed by thickness in gauges. Now, gauges are a way to measure thickness, and the smaller the number, the thicker the sheet. For example, a 10 gauge sheet is thicker than a 12 gauge one. You’ll find GI sheets in a variety of gauges, like 8, 9, 10, and so on, each one with its own weight and strength.

- 8 gauge: About 0.168 inches thick

- 9 gauge: Around 0.153 inches thick

- 10 gauge: Roughly 0.138 inches thick

- 11 gauge: Close to 0.123 inches thick

Now, these sheets can be used in all sorts of ways. You can find ’em in roofs, fences, and even used for making pipes. They’re strong, and they don’t break easy, unlike some of them other materials that are more brittle. The zinc layer helps make sure the steel don’t start to rust, even if the sheets get a little wet now and then. That’s why folks use them for things like water pipes or roofing material where you don’t want to deal with rust every few years.

Where do we use GI sheets? Well, they’re good for all kinds of jobs. If you’re puttin’ up a new fence or need some strong roofing for your barn, you might wanna think about GI sheets. Heck, they’re also good for making some of them big, strong pipes you see running under the ground or carrying water to your house. And because they’re covered in zinc, they don’t rust out like them old-fashioned iron pipes did. You won’t have to worry about replacing ‘em too soon.

Another thing, these sheets come in different sizes too. You can get ‘em in big sheets or even coils. If you need to cut them down to size, you can do that pretty easily, though you might need some special tools to get through the thick stuff. Don’t go thinkin’ you can cut through a big ol’ sheet with just a pair of scissors!

What’s the difference between GI and GP sheets? Now, I know some of you might be wonderin’ if GI sheets are the same as GP sheets. They sound pretty similar, don’t they? But there’s a little difference. GI sheets are coated by a hot-dip process, meaning the steel gets dipped right into a bath of hot zinc. GP sheets, on the other hand, are made by electroplating them with zinc. It’s a bit of a different process, but they both help keep the steel from rustin’ out.

One thing about GI sheets is they’re mighty tough. Sure, they’re not perfect, and nothing lasts forever, but they hold up way better than most things out there. The zinc layer might wear down a bit over time, but it’s still better than having plain steel that’ll rust away in no time. And if you’ve ever had to fix up a rusty old fence or roof, you know just how important that protection is.

In the end, why choose GI sheets? Well, if you want something that’s gonna last, that’s why. They’re tough, durable, and resistant to rust. Whether it’s for building, roofing, or pipes, GI sheets get the job done without all the hassle of constant repairs or replacements. And because they come in all sorts of thicknesses and sizes, you can find just the right one for whatever project you’re workin’ on.

So next time you’re thinkin’ about what kind of steel sheet to use for your next project, don’t forget about that good ol’ GI sheet. It might not be the fancy name you see on TV, but it sure does the job. And in the end, that’s what matters most, ain’t it?

Tags:[GI Sheets, Galvanized Iron, Steel Sheets, Zinc Coating, Corrosion Protection, Durable Metal Sheets, Roofing, Fencing, Metal Pipes, Hot Dip Galvanization]