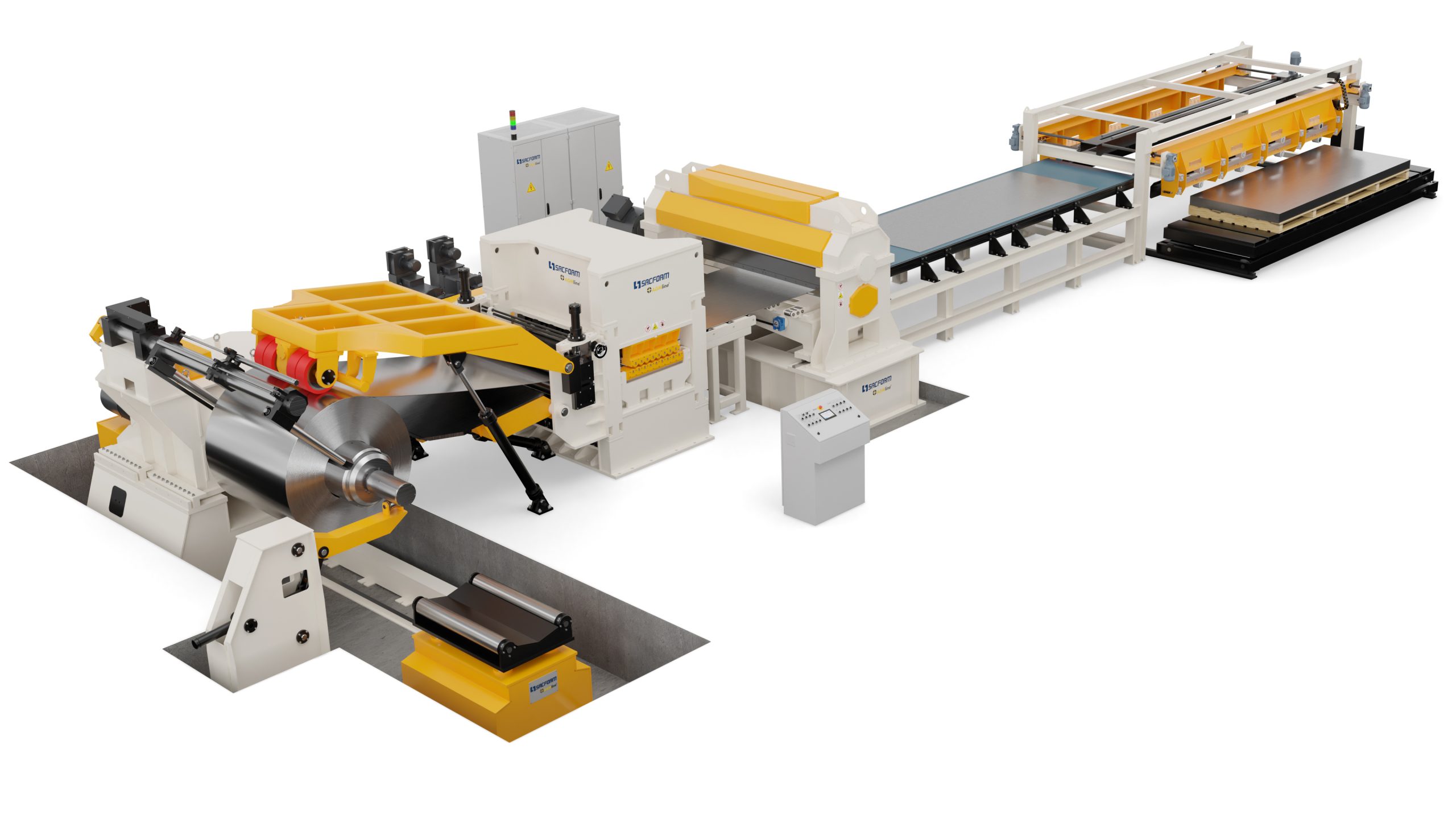

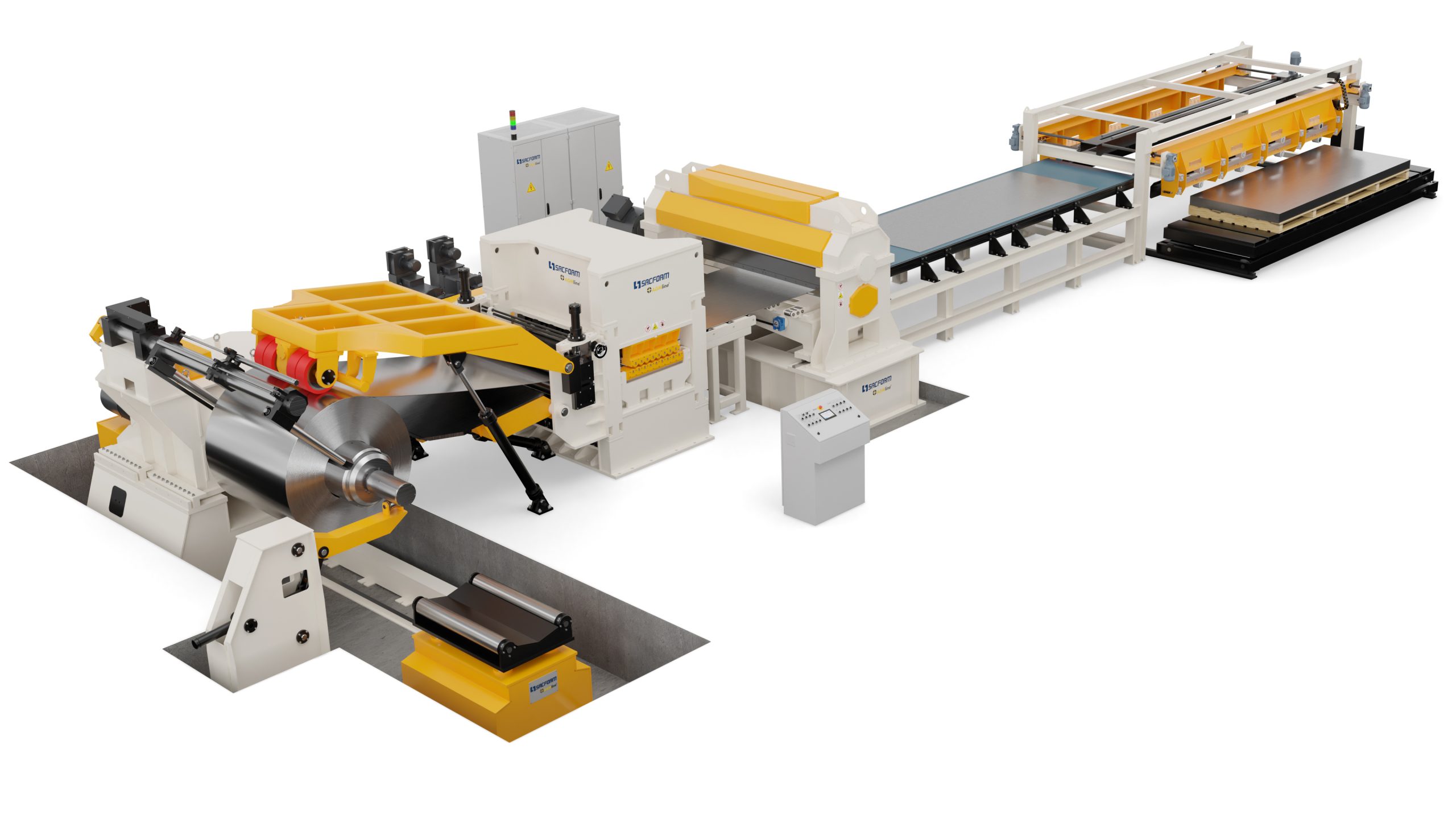

You know, them cut to length lines, well, they’re real handy for dealing with them big steel coils. What happens is, they take them big ol’ steel rolls, unroll ’em nice and flat, and then they cut ’em just right to the length you want. Now, I ain’t no expert, but it’s kinda like when you got a big ol’ roll of cloth, and you just want a piece the size of your window. That’s how they do it with steel, but it’s a lot more work than just cuttin’ cloth.

So, these cut to length lines, or folks also call ’em blanking lines, or sometimes shear lines, are used to make sure the steel is nice and flat before they cut it. They use big machines to do this. These machines, they unroll the steel, and then they level it out, like smoothing a bedsheet, just makin’ sure there ain’t no bumps or curls. Once that’s done, they go ahead and cut it to the size you need. Could be big sheets or small ones, depends on what ya need.

Now, lemme tell ya how this works. The steel comes in big coils, right? So first thing, the machine unrolls the steel, kinda like when you’re tryin’ to unroll a rug that’s been sittin’ in the attic too long, all curled up. After that, it gets leveled out, which just means they make it all flat, no wrinkles or nothin’. Then it goes through these big ol’ blades, and cuts the steel to the length you want, exactly as you need it, no more, no less.

There’s different kinds of shears they use for this. Some folks use rotary shears, which just spin around to cut the steel, kinda like them scissors you use for cuttin’ paper, but way stronger. Others use stationary shears, which stay in one spot and chop the steel. No matter which one they use, though, the result is the same – you get a steel sheet that’s cut just right.

Oh, and they can cut some big stuff, too! Them machines can handle steel coils that weigh up to 40 tons, and the strip width – that’s how wide the steel is – can be as wide as 86 inches! That’s a mighty big piece of steel, if you ask me. But these machines, they handle it just fine.

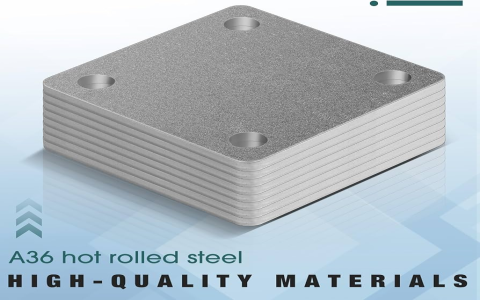

It’s not just about cuttin’, though. You gotta make sure the steel is cut with precise tolerances. That’s just a fancy way of sayin’ they need to make sure the cuts are just right, no mistakes allowed. If it’s even a little bit off, it can mess up the whole thing. So, them machines, they work real careful, measure twice, cut once, like my granddaddy always said.

So why do folks need these cut to length lines? Well, it’s simple, really. If you’re buildin’ somethin’ like cars or bridges or even kitchen appliances, you need steel that’s the right size, right? You can’t just go to the store and buy a roll of steel and hope it fits. Nope, you need it cut exactly how you need it, and that’s where these machines come in. They do the hard work for ya.

- First, they uncoil the steel.

- Then, they level it out to make sure it’s all flat.

- Next, they use them shears to cut the steel to the length you need.

- Finally, you got yourself a nice, clean piece of steel, ready to be used in whatever project you got goin’ on.

It’s a pretty neat process if you ask me. So, next time you see somethin’ made of steel, whether it’s a car, a bridge, or maybe even your fridge, just remember, there’s a good chance that steel went through one of them cut to length lines to get just the right size. Ain’t that somethin’?

Tags:[cut to length lines, steel coils, shear lines, blanking lines, rotary shears, stationary shears, steel cutting]