Listen up, y’all, let’s talk ’bout them rolled steel beams. I ain’t no fancy engineer, but I know a thing or two ’bout these metal thingamajigs.

You see, they use ’em for all sorts of stuff. Big machines, yeah, them heavy-duty ones, they got steel beams holdin’ ’em up. And buildings too, the big tall ones and the small ones, they need somethin’ strong to keep ’em from fallin’ down, right? That’s where these steel beams come in handy.

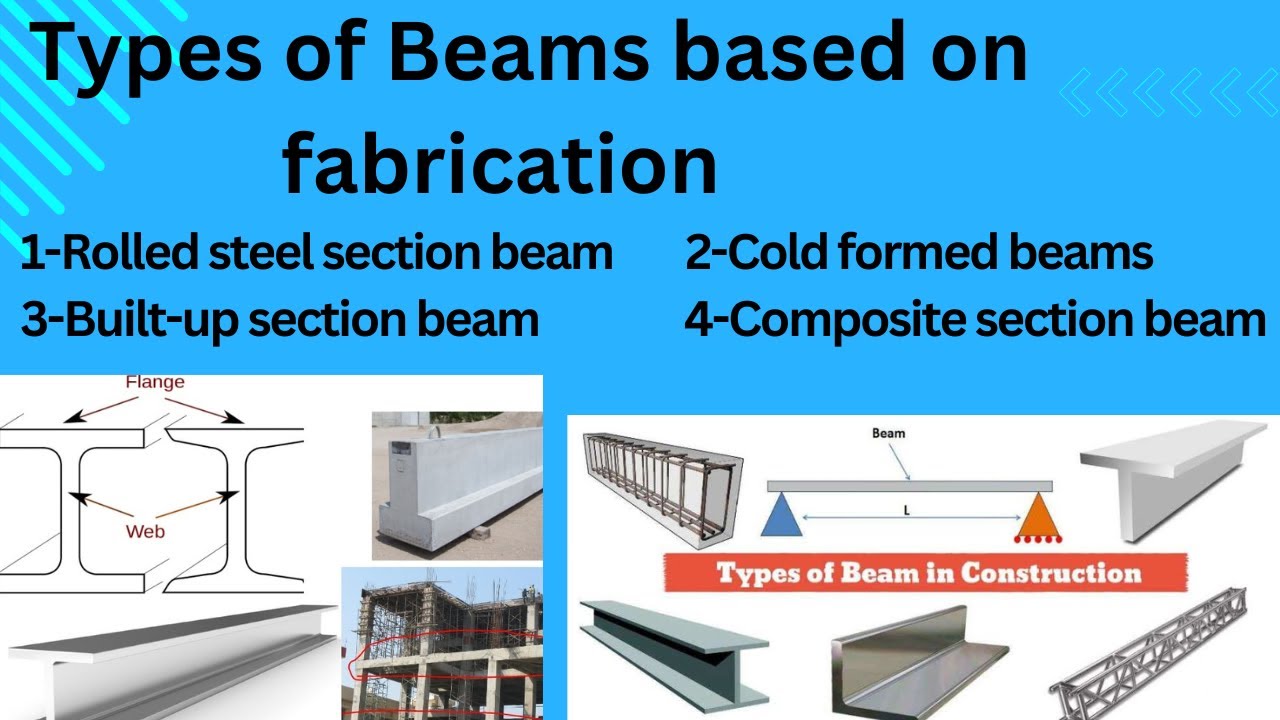

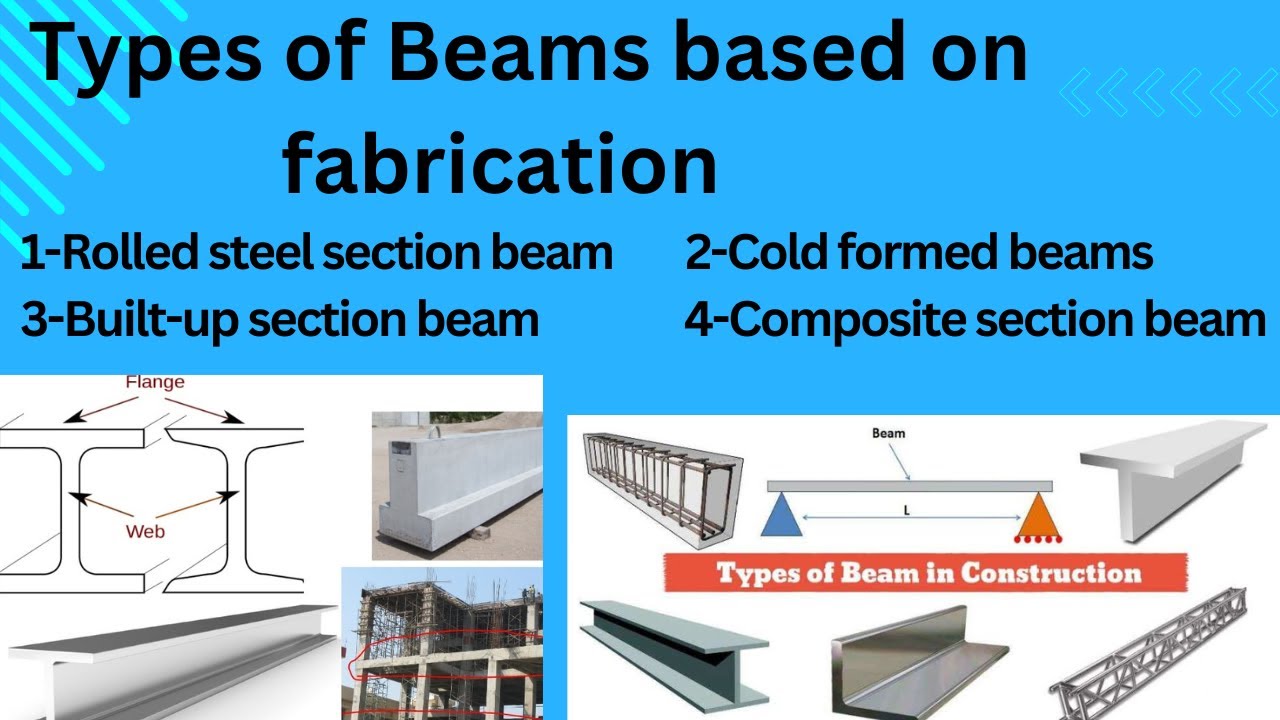

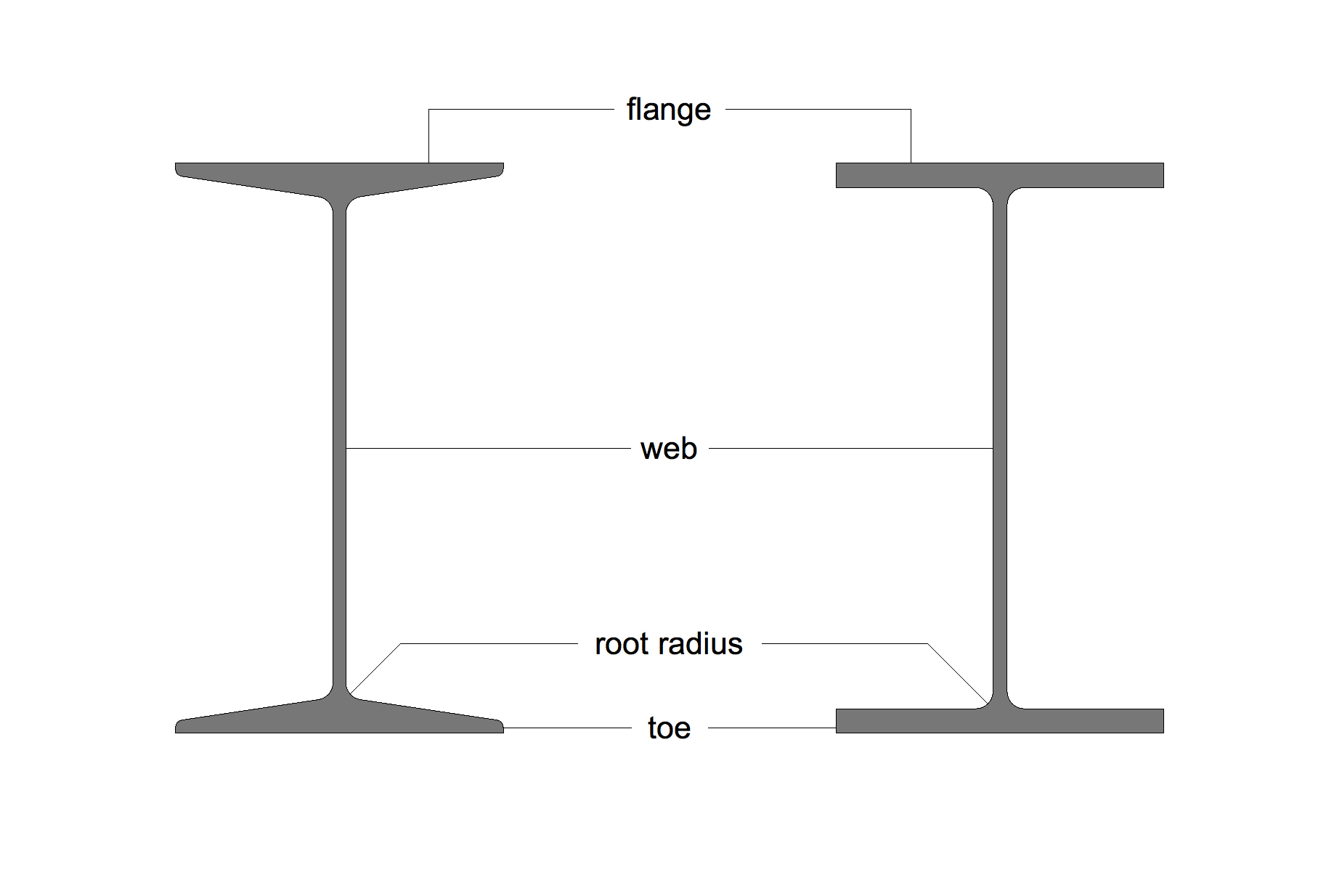

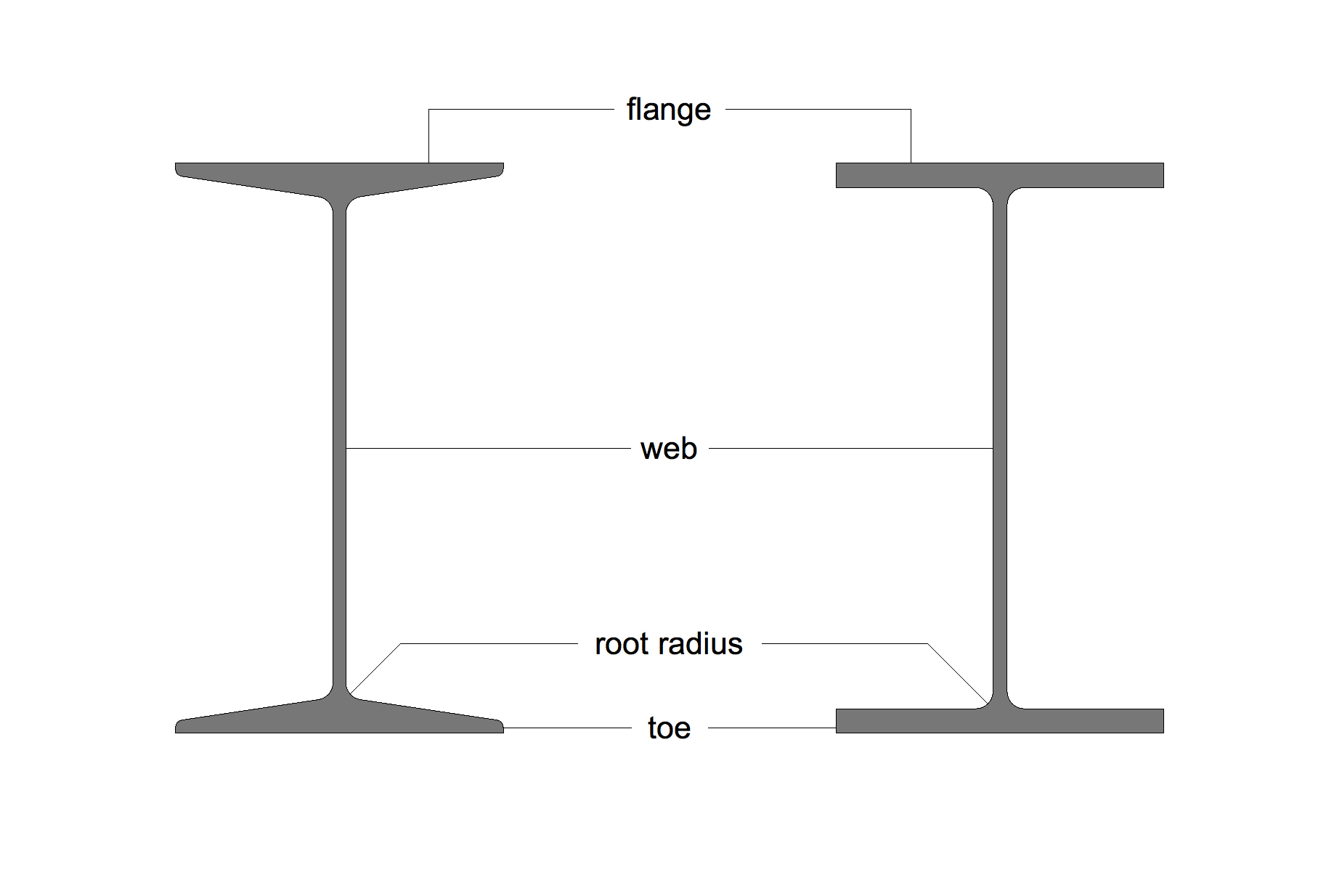

Now, they come in all sorts of shapes and sizes, like letters, you know? Some look like a “T”, they call ’em T-beams or T-sections. Then there’s others, but I ain’t gonna get into all that fancy stuff. Point is, they’re strong and they hold things up, that’s what matters.

- Steel’s strong, real strong. Stronger than wood, that’s for sure.

- They use steel beams in lots of places. Big machines, buildings, all sorts of stuff.

- Lots of different types of steel beams, all shapes and sizes.

So how do they figure out what kind of beam to use? Well, them engineer fellas, they do a bunch of calculatin’. They gotta figure out how much weight the beam needs to hold, how long it needs to be, all that jazz. It ain’t just guessin’, you know? They got their fancy formulas and numbers and stuff. I ain’t got no clue about all that, but I know it’s important.

Designing a Rolled Steel Beam – a Simple Way to Look at it

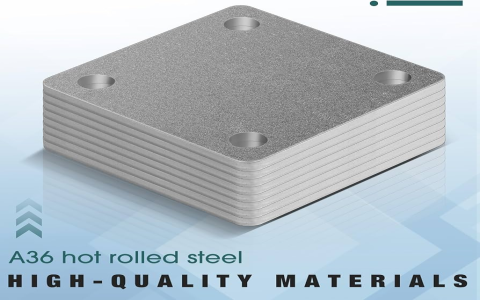

First off, they gotta decide what the beam’s gonna be made of. Most times it’s steel, but sometimes they use wood too. But we’re talkin’ ’bout steel here, so let’s stick to that. Then they gotta figure out what shape it needs to be. Like I said, “T” shapes are common, but there’s others. It all depends on what it’s gotta do.

Next, they gotta figure out how much weight it’s gotta hold. This is the important part, you don’t want the thing to break, right? They call it the “maximum load” or somethin’ like that. Fancy words for how much stuff you can put on it before it comes crashin’ down. They use all sorts of numbers and formulas for this, way over my head, but they know what they’re doin’, I guess.

After that, they gotta pick the right size beam. It can’t be too small or it’ll break, and it can’t be too big or it’ll be a waste of money. They got charts and tables and stuff, tellin’ ’em exactly what size beam to use for different weights and lengths. It’s like a recipe, you gotta follow it or you’ll mess things up.

And then, they gotta make sure the beam is safe. They check it for all sorts of things, like bendin’ and twistin’. They don’t want it to buckle under pressure, you know? They got rules and regulations they gotta follow, make sure everything’s up to snuff. Safety first, that’s what they always say.

So, there you have it, a little bit ’bout them rolled steel beams. They’re strong, they’re useful, and they keep things from fallin’ down. And them engineers, they know how to figure out all the fancy stuff to make sure everything’s safe and sound. It’s more than just eyeballing it, that’s for sure. They use all sorts of math and science to make sure them beams do their job.

Understanding Rolled Steel Beams: Uses, Types, and Sizes

Now, if you wanna get into the nitty-gritty, there’s lots more to learn. You can read up on the different types of steel beams, their classifications, and how to read the sizes. It’s like a whole ‘nother language, all them numbers and letters. But if you’re just tryin’ to understand the basics, well, I think I covered most of it. They’re strong, they hold things up, and they come in all shapes and sizes. That’s the long and short of it, far as I’m concerned.

And remember, whether it’s a big ol’ skyscraper or a piece of heavy machinery, chances are there’s some rolled steel beams doin’ the heavy liftin’. They’re the unsung heroes of the construction world, if you ask me. Just like a good strong cup of coffee in the mornin’, they keep things goin’ and get the job done.