Introduction to ZAM Steel Coil: Benefits, Features, and Applications

What is ZAM Steel Coil?

ZAM (Zinc, Aluminum, Magnesium) steel coil is a high-performance steel product coated with a unique alloy consisting of zinc, aluminum, and magnesium. The alloy coating provides superior corrosion resistance, making ZAM steel coils an ideal choice for a wide range of industrial and commercial applications. The ZAM coating enhances the durability of steel, ensuring longer lifespan and better resistance to environmental factors such as moisture, salt, and temperature fluctuations. ZAM steel is commonly used in the automotive, construction, and energy sectors for components exposed to harsh environmental conditions.

Benefits of ZAM Steel Coil

- Superior Corrosion Resistance

One of the key advantages of ZAM steel coils is their exceptional resistance to corrosion. The combination of zinc, aluminum, and magnesium in the coating forms a durable barrier against rust and oxidation, even in highly corrosive environments such as coastal regions or areas with high humidity and pollution. - Longer Lifespan

ZAM steel coils have a significantly longer service life compared to traditional galvanized steel. The unique alloy coating protects the steel from corrosion, reducing the need for frequent replacements and maintenance, making it a cost-effective choice for long-term applications. - Enhanced Durability

The alloy coating of ZAM steel provides greater resistance to wear, scratching, and abrasion, which makes it ideal for heavy-duty applications. This durability ensures that the material can withstand harsh conditions, such as extreme weather or exposure to chemicals. - Improved Formability and Strength

ZAM steel coils maintain the strength and formability of traditional steel while providing superior corrosion protection. This makes them suitable for manufacturing complex shapes and structures without compromising on mechanical properties. - Environmental Sustainability

ZAM steel is an environmentally friendly option, as it provides superior protection with a thinner coating than conventional galvanized materials. Moreover, it is fully recyclable, making it an eco-conscious choice for sustainable building practices. - Aesthetic Flexibility

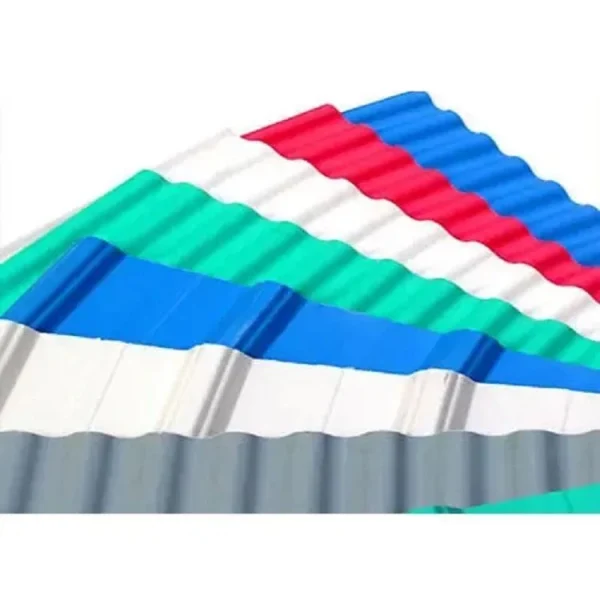

ZAM steel coils can be produced in various finishes and colors, allowing for greater flexibility in design and aesthetics. Whether for industrial or architectural applications, ZAM steel can meet both functional and visual requirements.

Applications of ZAM Steel Coil

- Automotive Industry

ZAM steel coils are widely used in the automotive industry for parts that require both strength and corrosion resistance, such as body panels, exhaust systems, and chassis components. The enhanced corrosion resistance of ZAM steel helps protect vehicles from rust and ensures longevity even in harsh road conditions. - Construction and Building Materials

In the construction sector, ZAM steel coils are used for roofing, cladding, and structural components. Their excellent resistance to corrosion makes them ideal for use in buildings exposed to harsh weather conditions, including coastal or industrial environments. ZAM steel is also used in the manufacture of durable doors, windows, and fencing. - Energy Industry

ZAM steel coils are employed in energy-related applications, including the production of solar panels, power transmission components, and offshore oil platforms. The alloy’s corrosion resistance is crucial for equipment exposed to extreme environmental conditions, such as saltwater or industrial pollutants. - Agricultural Equipment

Agricultural machinery, storage containers, and barns made from ZAM steel benefit from its durability and resistance to corrosion. ZAM-coated steel can withstand the rough conditions of agricultural environments, including exposure to moisture, chemicals, and extreme weather. - Marine Applications

ZAM steel is highly resistant to corrosion caused by saltwater, making it an ideal choice for marine applications such as shipbuilding, boat parts, and marine infrastructure. It helps extend the life of equipment and structures exposed to the harsh marine environment. - Appliance Manufacturing

The appliance industry also benefits from ZAM steel coils in the production of refrigerators, washing machines, and other household appliances. The material’s durability, resistance to corrosion, and appealing finish make it a popular choice for both external components and internal parts exposed to moisture.

Comparison with Other Coated Steels

ZAM steel coils stand out in comparison to other coated steel products like galvanized or galvalume steel due to their enhanced corrosion resistance and durability. While galvanized steel is coated with a layer of zinc and offers basic protection, ZAM’s inclusion of magnesium provides a more robust barrier against environmental factors, especially in harsh or coastal climates. Compared to galvalume (which uses a zinc-aluminum coating), ZAM offers superior long-term protection and better performance in highly corrosive environments.